Beyond Access: Scaffolding As A Sitewide Safety Enhancement

Scaffolding plays a vital role in industrial construction, providing a safe and efficient means for workers to access elevated areas and perform their tasks. AMECO’s Integrated Scaffold Solution has been shown to reduce indirect field labor costs on major industrial greenfield projects , can improve efficiency in shutdown and turnaround projects where every second counts, and in a head-to-head competition with ringlock and cuplock systems , our Integrated Scaffold Solution was a clear winner.

However there is another reason to explore modernizing the approach to scaffolding in industrial construction: Choosing the right scaffolding partner can be a project-level safety enhancement.

Safety In the Oil & Gas Industry

We analyzed a recent Gulf Coast oil and gas project that utilized the AMECO Integrated

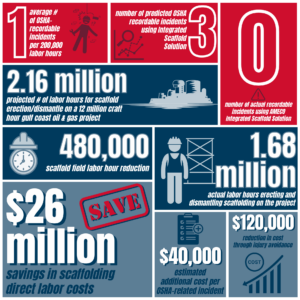

Scaffold Solution. The project planners estimated needing about 2.16 million labor hours for scaffold erection and dismantle. Based on historical industry averages, we would anticipate three OSHA-recordable incidents with the craft teams installing the scaffolding over that many hours. But that’s not what happened.

Here’s a closer look at the results:

- Fewer labor hours were required: Through rigorous planning and benefits that come with working with the PERI Up scaffolding system, AMECO was able to provide scaffolding erection and dismantling in 1.68 million labor hours.

- Zero OSHA-recordable incidents: There were no OSHA recordable safety incidents on the AMECO team during the 1.68 million hours it took to build and remove the scaffold structures.

- 480,000 fewer labor hours: Not only does the almost half a million labor hours difference reduce direct labor costs for site access, it drastically reduces exposure.

- Savings on Savings: Not only was there about $26 million in labor savings with the 480,000 labor hour reduction, there is also savings in eliminating estimated OSHA-recordable incidents. At an estimated $40,000 added cost per recordable incident, eliminating safety incidents saved the project an additional $120,000.

- And most importantly, no one was injured while installing or dismantling the scaffolds.

Safety + Sustainability

With the AMECO Integrated Scaffold Solution, safety and sustainability are two sides of the same coin. Many of the safety enhancements of the material used in the Integrated Scaffold Solution can be counted on as sustainability improvements as well.

With modular decking, AMECO never uses lumber for floorboards or toeboards. The PERI Up decking material is engineered to not warp in the elements, drain water to prevent slipping, and increase traction in icy conditions. And these safer decks are reusable and don’t end up in the landfill pile.

In addition, decking is secured by patented gravity locks, eliminating the need for No. 9 Tie Wire. Eliminating the wire improves safety by eliminating repetitive handwork and benefits sustainability by eliminating waste at the end of the project.

MORE:

- How integrating Site Services improves construction outcomes

- See it, believe it – PERI Scaffolding vs. Ringlock and Cuplock

- Construction Safety Week – Scaffold Safety